Here at Rockshield EWP, we strive for excellence, leadership, sustainability and competitive advantage with integrity through continual improvement in our environmental performance and management of forest land. For us, sustainable development means creating economic growth while caring for our society and environment.

One of our goals as a company is to engage personally with local business owners and community members in order to communicate future plans, listen to concerns and act as an excellent corporate citizen within our community. Rockshield EWP believes in maintaining transparency throughout mill offices and operations. We believe that we owe our community, clients, visitors, partners and staff disclosure and accuracy.

Sports sponsorship, volunteering, community events and food bank donations are just some of the contributions Rockshield EWP provides to the community.

Sustainability and the Environment

Not only does aspen produce superior hardwood plywood, it is also one of the best species for sustainable forestry. Aspen naturally regenerates from root saplings once the main trunk has been harvested.

Aspen is a post disturbance species; this means that when an area of aspen trees is harvested, regeneration occurs naturally through the root system. On an acre of harvested aspen, 6,000 to 8,000 aspen trees sprout. Through the natural selection process, 300 to 400 of the strongest trees will survive to become the new and healthy forest. This ensures we are supplying the highest quality hardwood plywood for generations to come.

Our belief in sustainable development means we are committed to:

Rockshield EWP is proud that a number of our employees are professionally trained foresters. They, along with all the people working in the mill, live, work and play in the area. Each one of them is dedicated to sound, sustainable, responsible forestry practices. This ensures they have a place to camp, hunt and fish, as well as work, for many generations to come. Additionally, all forest plans are prepared by Registered Professional Foresters and all public lands are independently audited every five years to ensure that the forests are being managed in a sustainable manner.

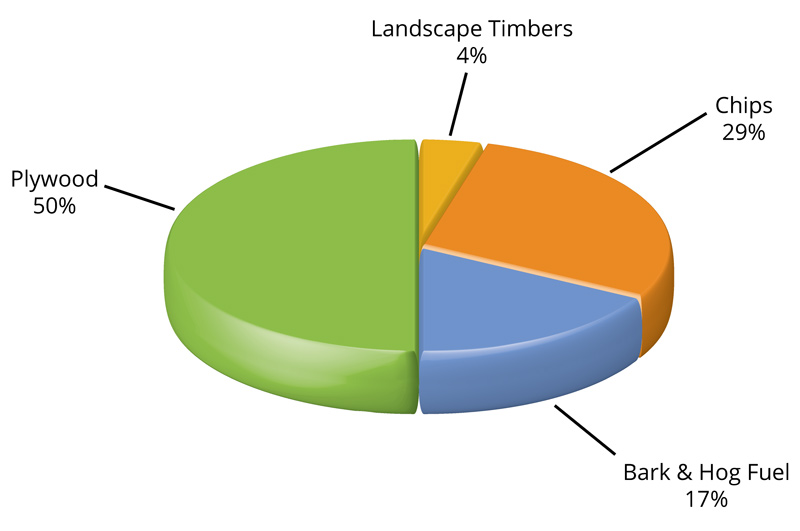

All of our mill’s by-products are used so that there is almost no waste involved in our processing.

We support our environment through sustainable forestry practices, careful management and evaluation of our processes and our commitment to using all parts of our wood.

Our commitment to the environment doesn’t stop at our forestry practices; none of the log is wasted at our mill:

- Bark, sawdust and other wood waste is sold to a local bio-mass cogeneration facility to produce electricity;

- Peeler blocks are rotary peeled down to a 4”-5” diameter core which may be sold round or may be canted (flat on two sides) and sold as landscape timbers;

- Waste veneer is chipped and sold to pulp mills.

Our Commitment to Safety

We are committed to safeguarding the health and well-being of our employees, contractors, and visitors by creating and maintaining a safe work environment.

We believe that:

- All injuries and occupational illnesses are preventable;

- Health and safety is a top priority and an integral part of our business and decision-making;

- Management is ultimately responsible for workplace health and safety;

- Safe operating practices are a shared responsibility among management, employees, contractors and visitors;

- Employees and contractors are accountable for their safety and that of fellow workers;

- Working safely is a condition of employment;

- Sharing best practices improves performance.

Rockshield EWP creates a safe work environment by:

- Designing safe facilities;

- Continually reviewing and improving processes and procedures;

- Identifying hazards and assess risks;

- Developing, implementing and enforcing safe work practices;

- Ensuring all facilities comply with applicable laws and regulations;

- Providing employees with information and training to work safely;

- Requiring employees and contractors to execute their work in accordance with legislative requirements and Rockshield Engineered Wood Products ULC policy;

- Establishing and monitoring health and safety objectives;

- Taking action to prevent recurrence of incidents;

- Implementing health and safety management systems to continually improve performance;

- Conducting health and safety audits;

- Reporting health and safety performance to senior management, the Board of Directors, shareholders, employees, and the public.